Gland seal systems are very important to main and auxiliary turbines. Turbine shafts must exit their casings in order to couple up or connect with the unit that the turbines drive (reduction gears, pumps, etc.) The main and auxiliary gland seal systems enable the turbine to be sealed where the shaft exits the casing; in effect keeping “air out and steam in.” The purpose of the gland seal system is to prevent the leakage of air from the atmosphere into turbine casings and prevent the escape of steam from turbine casings into the atmosphere.

The gland sealing system provides low-pressure steam to the turbine gland in the final sets of labyrinth packing. This assists the labyrinth packing in sealing the turbine to prevent the entrance of air into the turbine, which would reduce or destroy the vacuum in the associated condenser. Excess pressure (excess gland seal) is removed by the gland seal unloader.

Since there are times when steam escapes from the seals, a gland exhaust system is provided. The gland exhaust system consists of low-pressure piping connected to the gland area between the last two outer sets of labyrinths which receives and prevents steam from escaping to the atmosphere. This system collects the steam and directs it to a condenser for further use in the steam plant.

Steam leaking from the gland seal area of the shaft packing, steam leak-off from the steam chest lift rods, and steam leak-off from the trip throttle valve is drawn into the gland exhaust system and into the air ejector condenser.

The steam is condensed in the SSTG air ejector condenser. Air and non-condensable gases are discharged to the atmosphere via the gland exhaust fan or Ejector which maintains a slight vacuum on the auxiliary air ejector condenser.

Most steam turbines have a shaft sealing system that uses carbon rings to isolate the rotor assemblies on both ends with steam injected to prevent air in-leakage into the turbine. The leakage would reduce turbine efficiency and flow into the condenser downstream of the turbine further reducing system efficiency. This gland steam must be removed by an ejector or exhaust fan to prevent it from flowing back into the turbine.

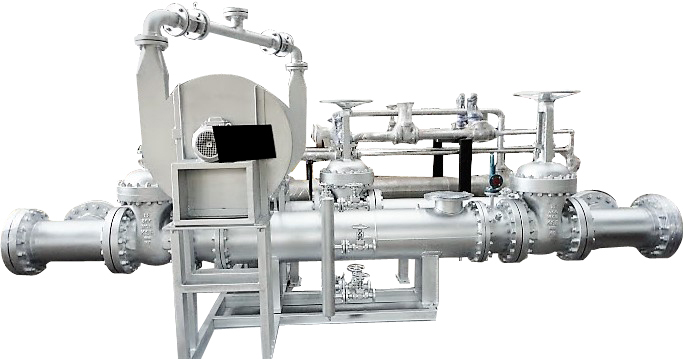

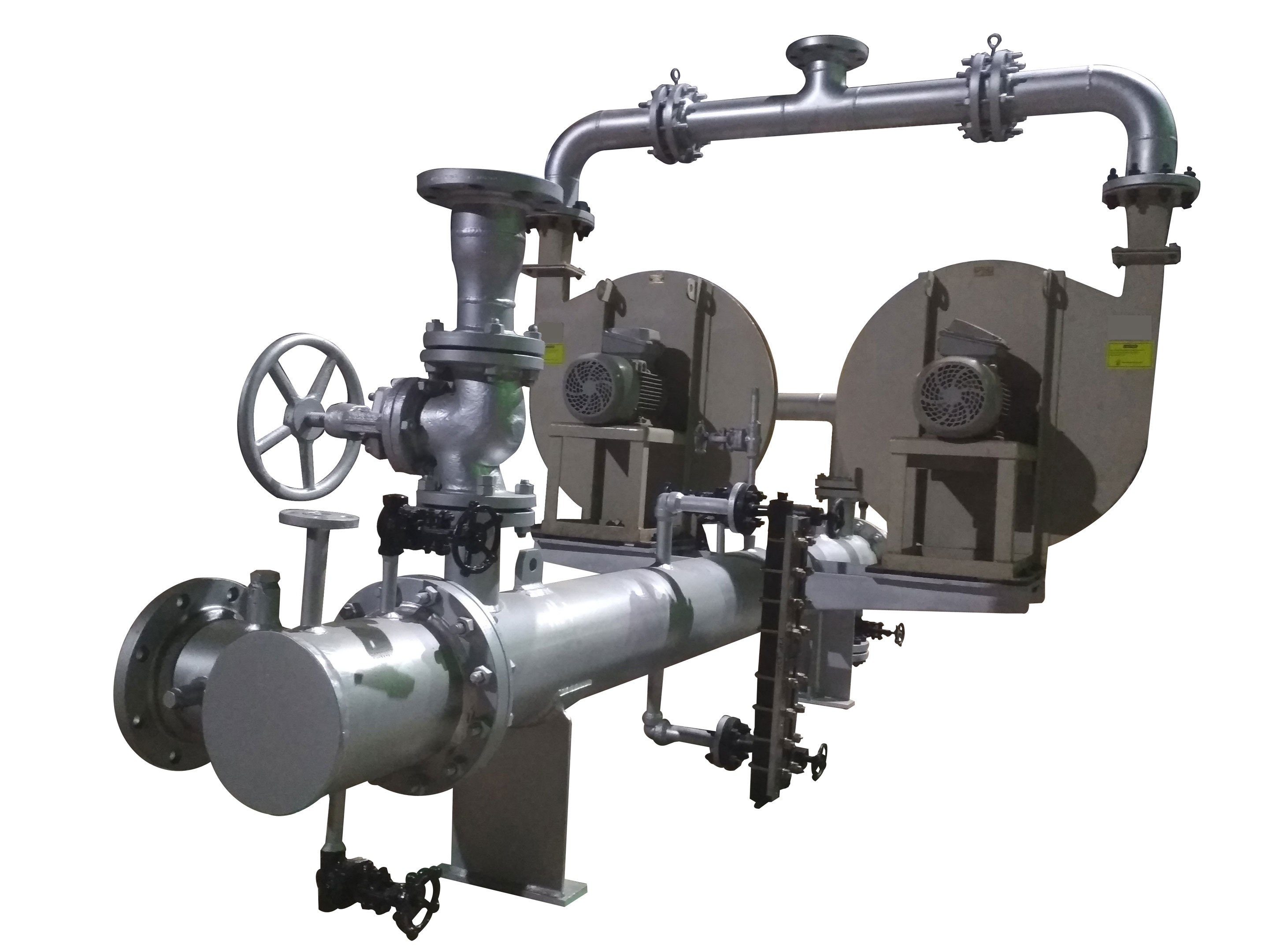

AAHANA Giffard system has superior technology and competitiveness for the basic and detailed design of Gland Steam Condensers which are installed in the thermoelectric, nuclear power plant. AAHANA carries out the vibration, stress analysis, and fatigue analysis to provide customers with improved quality and confidence. AAHANA has several experiences on major code and standards such as ASME, TEMA and also has experience on local regulation around the world such as PED, DOSH, and CSA.

Gland vent condensers in the UK - Gland vent condensers manufacturer in the UK - Gland vent condensers supplier in the UK - Gland vent condensers in the USA - Gland vent condensers manufacturer in the USA - Gland vent condensers supplier in the USA - Gland vent condensers in Germany - Gland vent condensers manufacturer in Germany - Gland vent condensers supplier in Germany - Gland vent condensers in Singapore - Gland vent condensers manufacturer in Singapore - Gland vent condensers supplier in Singapore - Gland vent condensers in India - Gland vent condensers manufacturer in India - Gland vent condensers supplier in India.