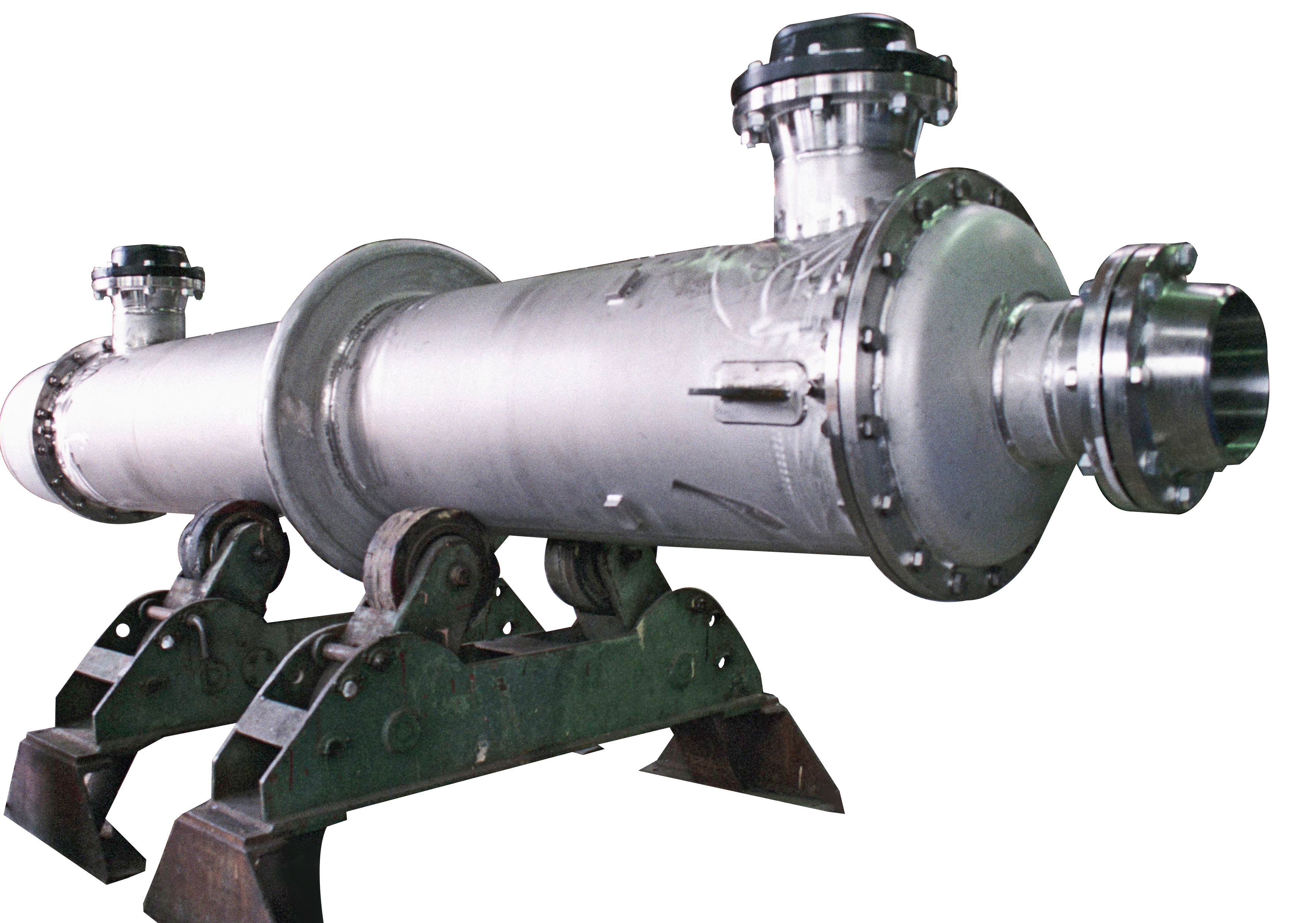

Power plants use a variety of Heat Exchangers to transfer heat between various fluids. The heat exchanger configuration is dictated by the thermal and hydraulic applications. AAHANA Heat Exchangers are designed using the Heat Transfer Research Institute (HTRI) programs, HTFS, and in-house design programs. The construction meets the standards of pressure guidelines as well as PED, API, ASME, or TEMA.

Each component of the Heat Exchanger is carefully designed to offer the highest heat transfer coefficient and the lowest pressure drop. Adequate flow areas are maintained in all sections of the Heat Exchanger to eliminate the detrimental effects of flow-induced vibration and erosion. Heat exchangers for unique applications with non-standard configurations, high temperature, high pressure, high cyclic service, and unusual fluid properties and materials are AAHANA’s specialty. Years of experience in design, fabrication, operation, and troubleshooting a wide range of heat transfer equipment permit AAHANA engineers to offer proven yet innovative solutions to achieve the unique requirements for performance and structural integrity. Complex thermal, hydraulic, and mechanical designs beyond the reach of the conventional approach are performed.

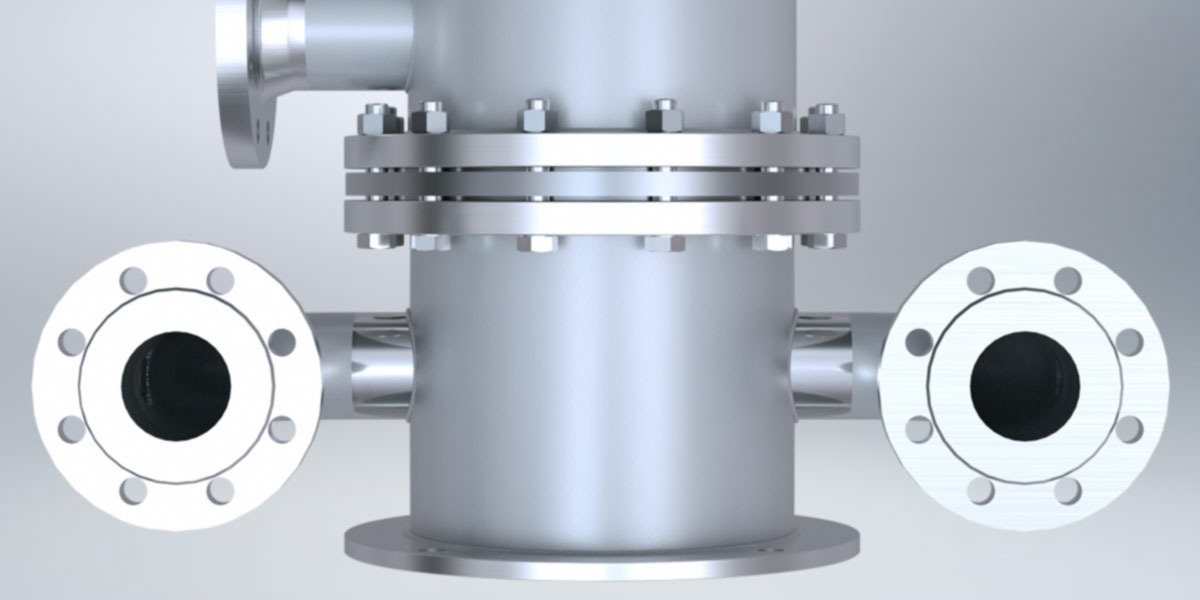

We design, manufacture, inspection, and test high-quality Vessels, tanks, flash vessels, Separators, and other fabricating items as per client requirements. We manufacture vessels from almost all materials i.e. Carbon Steel including NACE+HIC+SSC requirements, Stainless Steel, Monel, SS 904L, Cupro-Nickel, Admiralty Brass, Duplex SS, Inconel-600 / Incoalloy- 800, Hastalloy-B and C, Titanium, CS with Teflon lining, Graphite, FRP and CS with Rubber lining. All the fabricated items undergo stringent inspections and testing right from material receiving to all stage inspections, NDT, Leak testing, Final inspection, Painting inspection, packing, and marking inspection.

As a long-standing partner of leading global power plant constructors and suppliers, AAHANA Giffard System offers comprehensive knowledge in the design and manufacture of power plant components. The equipment developed by AAHANA is used in conventionally coal-, nuclear- or gas-fired power plants and in solar thermal or power plants powered by renewable resources.

Examples of our products: