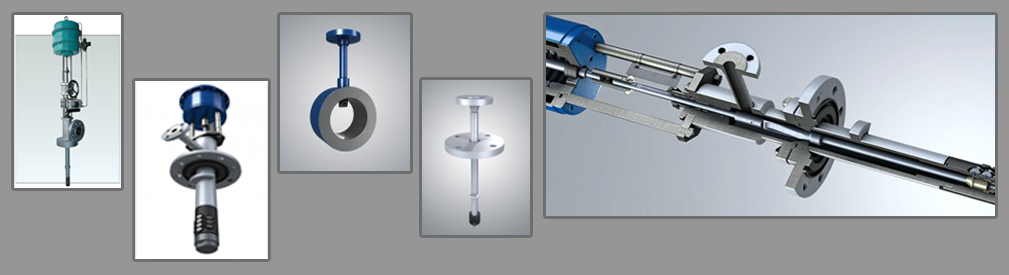

AAHANA Giffard Systems is a reliable Desuperheaters Manufacturer and Desuperheaters Supplier. We can manufacture and supply you with the following types of Desuperheaters.

Desuperheaters reduce the steam temperature by bringing superheated steam into direct contact with water. The steam is cooled through the evaporation of the water. Desuperheaters can be mounted either horizontally or vertically and are normally used for relatively steady load conditions where pressure losses must be minimized. These desuperheaters are a modification of the venturi-type unit. Without the venturi tail, and offer increased turndown when mounted vertically up.

Water enters the Desuperheater and is preheated in the circulatory chamber around the water diffuser tube. It is then introduced in many small jets to assist final atomization by the steam flow through the center of the throat. After leaving the throat, the mixture of steam and water enters the main steam flow in a fog-like condition where final heat transfer is achieved without contacting the sidewalls providing maximum desuperheating effectiveness with a minimum of pipe wear. Water pressure into the desuperheated should equal steam line pressure.

While it is less costly and has negligible pressure losses, it normally does not have the range-ability of the venturi-type unit. The actual turndown ratio is dependent upon a wide variety of factors. Such as installation, amount of residual superheats downstream. Piping, Etc. Normal flow variation is 75% to 15% of the flow.

Although requirements for desuperheaters cover a wide range of applications, the great majority fall into the following standard installations: