Fundamental Operating Principle of Smart Rod Systems

Fundamental Operating Principle of Smart Rod SystemsThe Smart Rod System increases the Zeta Potential through the utilisation of 30-35 KV DC high voltage. This increases the surface charge of colloidal particles, resulting in their repulsion from both wetted surfaces and one another. As a consequence, these particles remain in a state of suspension at all times. This prevents the accumulation of scale and biological fouling that would otherwise occur in water systems.

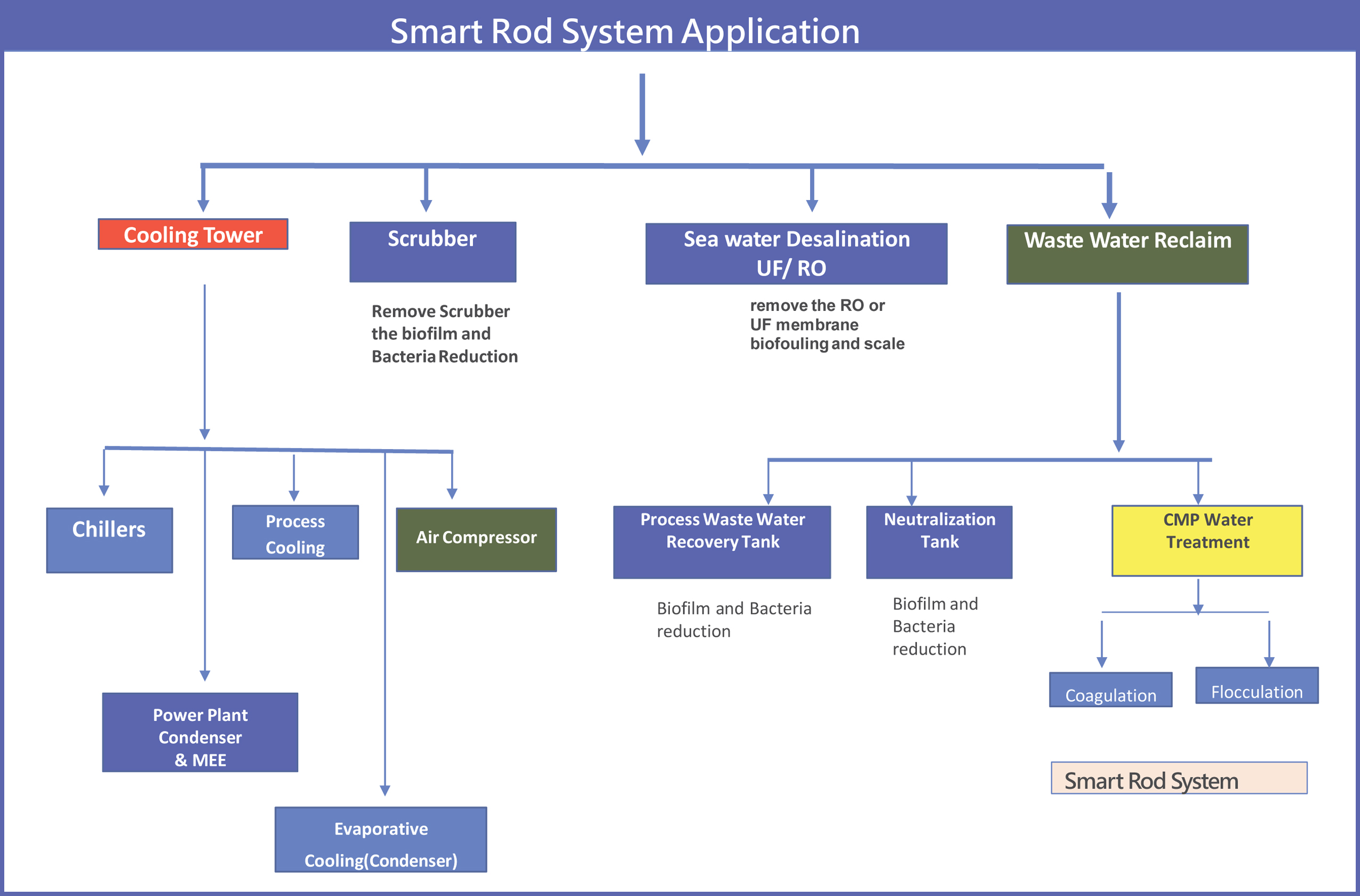

We are delighted to introduce the cutting-edge Smart Rod System (Advance Water Treatment Technology) from AGS, which eliminates the need for chemical solutions to address scale and biofouling concerns in heat exchangers, cooling towers, and membranes. With thousands of installations worldwide under the beltway of our principal partner, we are introducing the technology to India for the very first time. The Smart Rod System is a technological advancement that utilises high electrostatic repulsiveness to increase the Zeta potential in the fluid. This, in turn, guarantees that industrial applications will not experience any scale or biofouling issues.

Smart Rod Systems effectively eliminate and prevent algae growth, scaling, and biofilm formation, all while conserving energy by 2% to 10%. We are confident that you will recognise the enduring advantages of maintaining the high-potential Smart Rod System in operation to mitigate scaling and corrosion, as well as for maintenance purposes, in applications involving water-intensive processes such as cooling towers, chillers, condensers, RO plants, evaporators, and disk-to-plant units, as well as high purity WTP units MEE.

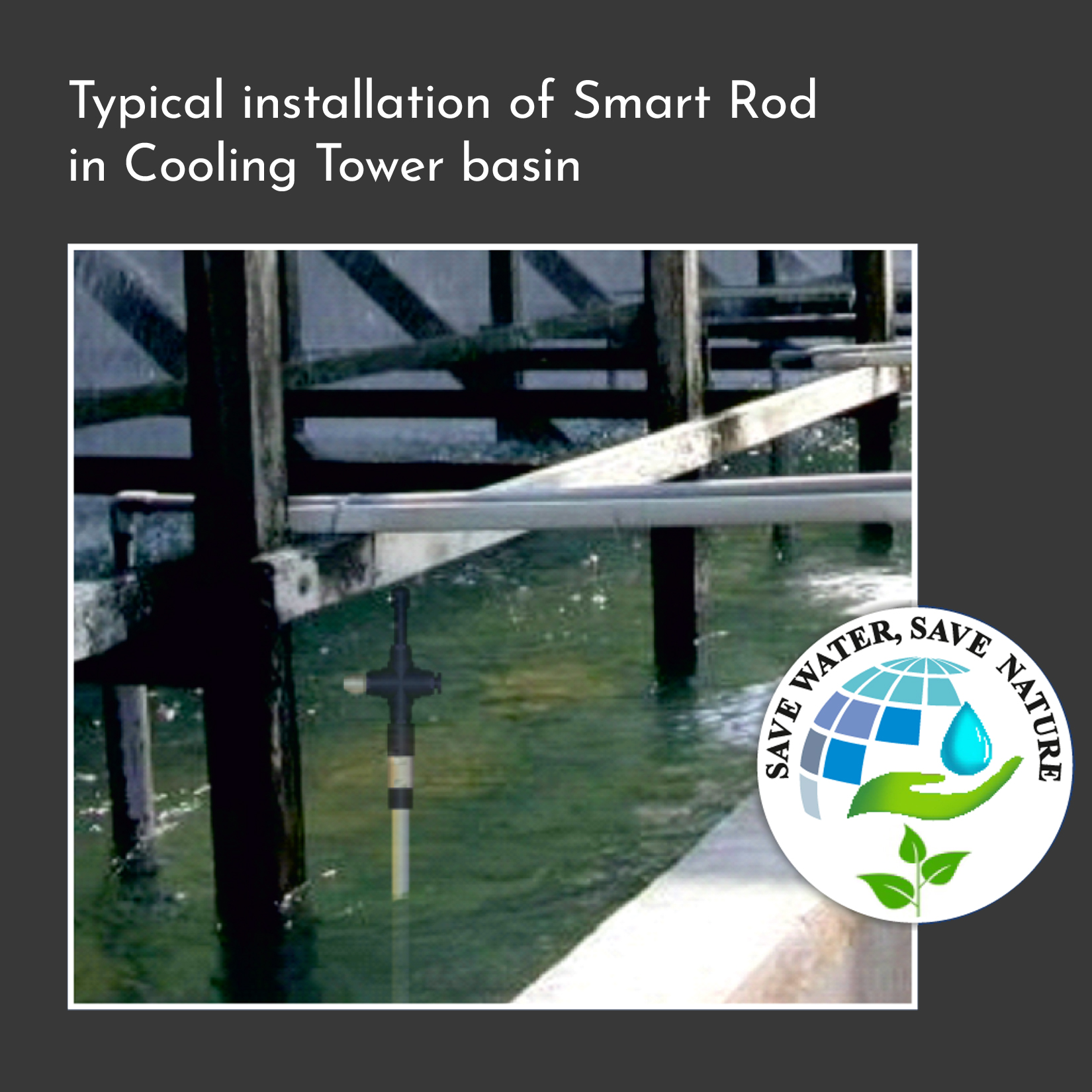

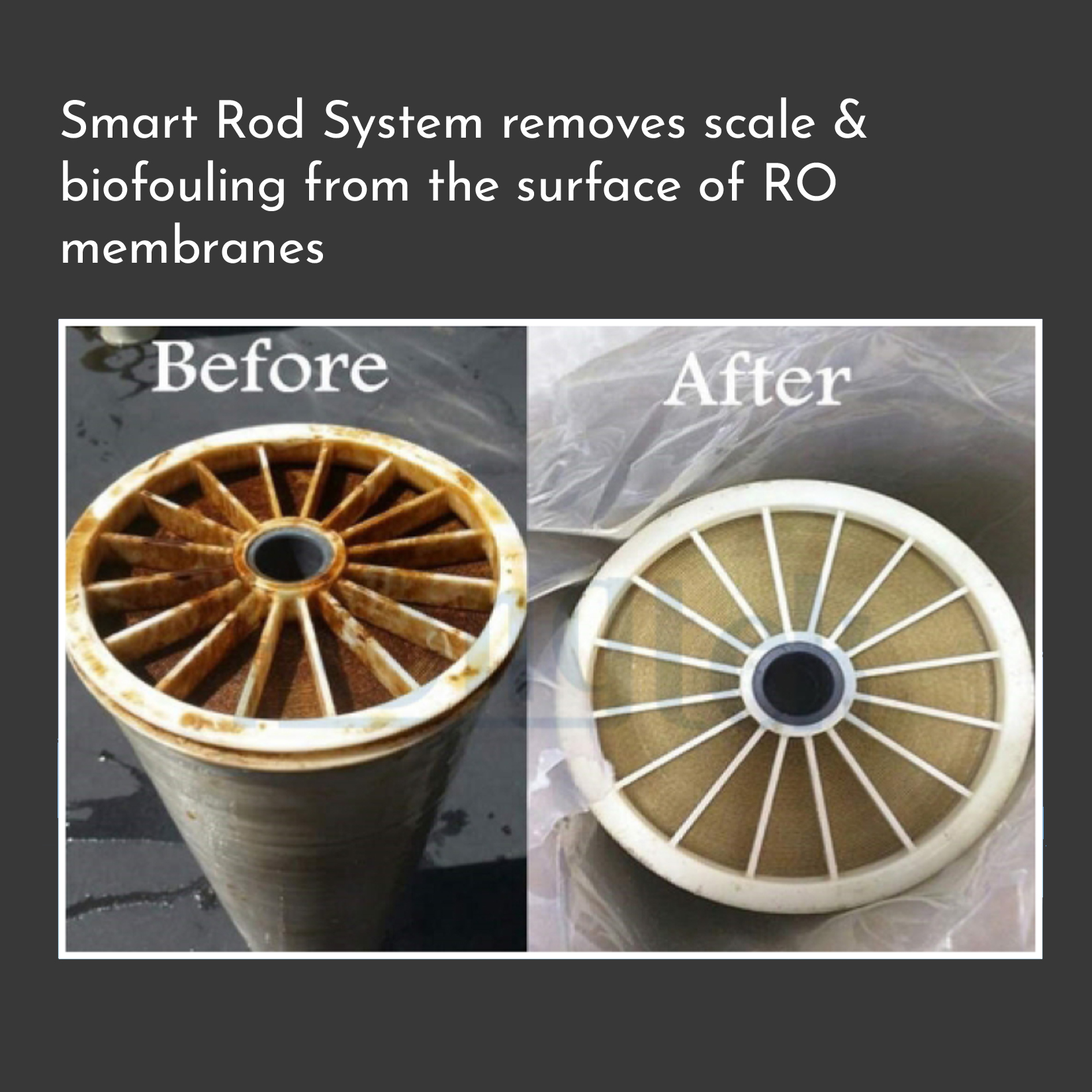

The Smart Rod System has the advantage of being installed in a RO plant, including piping, vassals, raw water storage tanks, cooling tower basins, chillers, heat exchangers, and condensers. It effectively addresses scaling and biofouling issues when operating at full capacity. In support of this claim, we offer a 100% money-back guarantee for a duration of 45-60 days. Should the equipment fail to meet your expectations in terms of efficient descaling/antiscaling and biofouling, we will gladly accept the equipment for refund.

1) For efficient and clean operation of cooling towers with greatly reduced make up water & blow-down frequencies (by enabling them to operate at relatively higher COC).

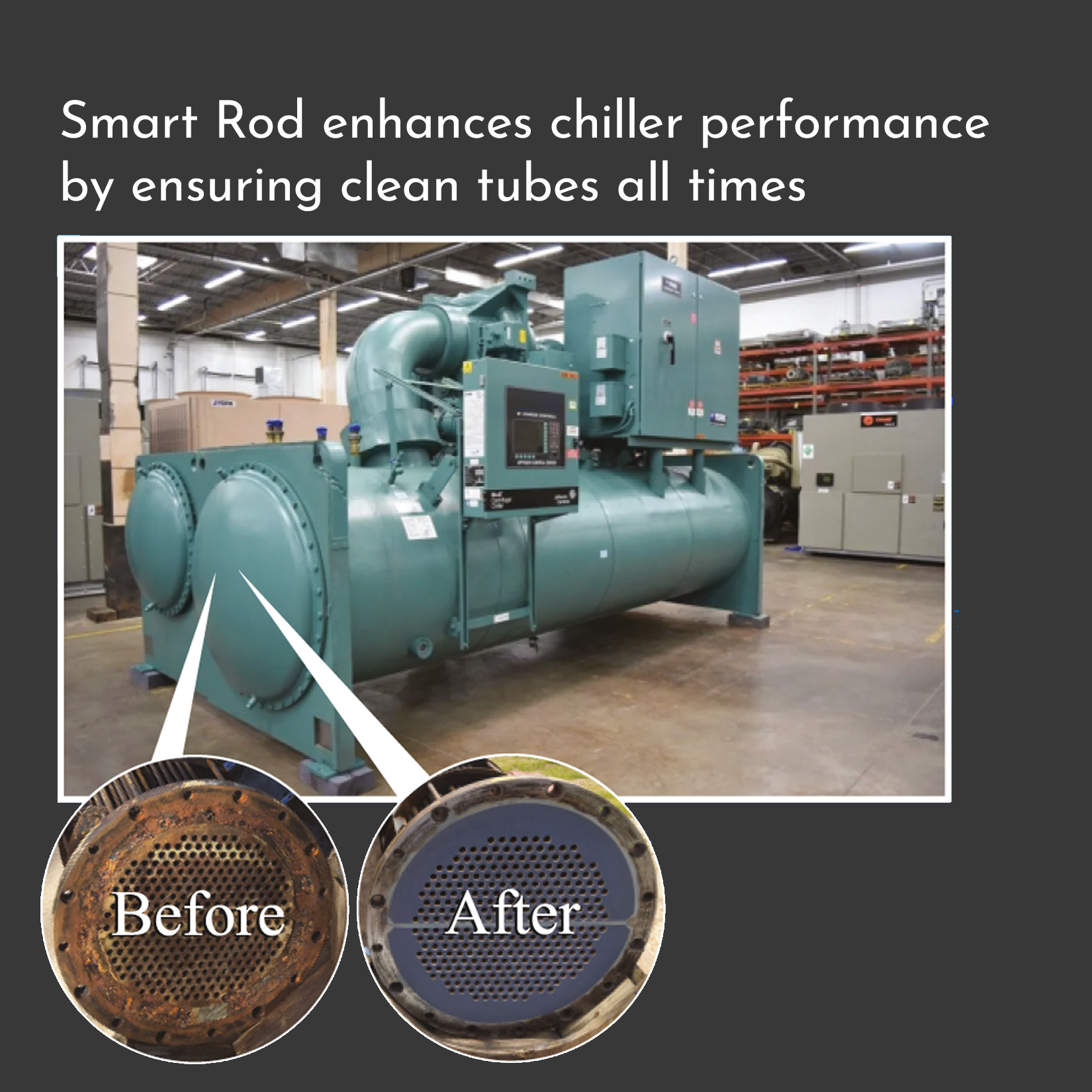

2) For consistent performance of Chillers by retarding the growth of scale and biofilm built-up in their Evaporators and Condensers.

3) For RO Membrane fouling prevention (for continuous and higher though put at all times) with significantly reduced CIPs and with increased membrane life span.

4) For enhanced performance of steam generators and small to medium sized boilers.

5) For optimised heat transfer of heat exchangers in CPI industries and surface Condensers in power plant ( by keeping their tubes clean at all times) and preventing expensive downtimes.

6) For continuous operation of MEEs to enable ETPs operate at full capacity at all times and reduce the CIP cycles.

Salient Features of Smart Rod Systems

Salient Features of Smart Rod Systems1) Easy to install and incorporate in existing set-ups being very compact in size.

2) No moving parts and therefore, practically nil maintenance.

3) Has very low operating cost as it consumes only around 0.005kw electricity.

4) Can be incorporated in stagnant as well as flowing water.

5) Can be scaled up for infinity capacity.

6) Mildly increase the pH level of water, reducing the corrosion rates of pipes, tubes and fittings.

7) Reduces load to the ETP systems due to lower water wastages and thus its operating cost.

8) Enables extremely fast payback periods due to reduction in usage of scale, biofilm and algae prevention chemicals, chemical storage space, reduced labours inputs & less water wastages.

1) The power supply that converts 90~240 V AC to 35KV high voltage DC through a transformer and provides a 35kv DC potential to the electrode and become a electrostatic field.

2) The electrode energized by connection a power supply.

3) When the electrode have been installed in pipe or vessel walls, the electrode and grounding surface form a capacitor.

4) Once the Smart Rod System has been energized, it creates a high voltage electrostatic field of the capacitor.

5) The Smart Rod System is an increase in the density of the surface charge of the particles in the water, boosting particle surface charge, which creates a stable dispersion effect.

6) This charging effect has powerful repulsion force to remove soft scale or biofilm, prevent the water system fouling deposition.