An Energy-Saving New Generation of Two-Stage Liquid Ring Vacuum Pumps

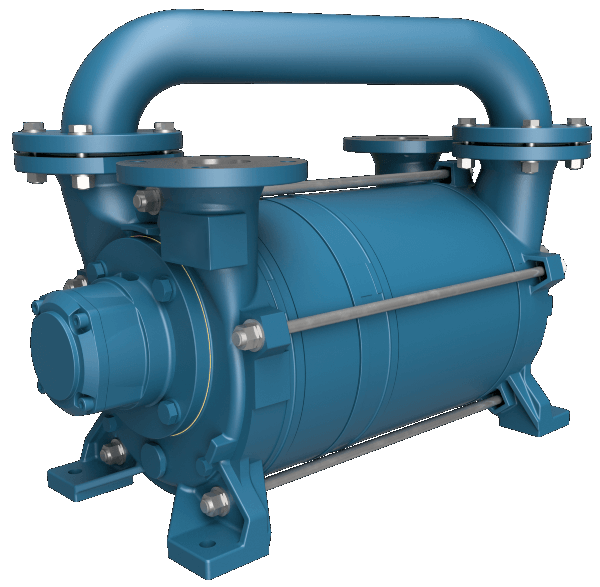

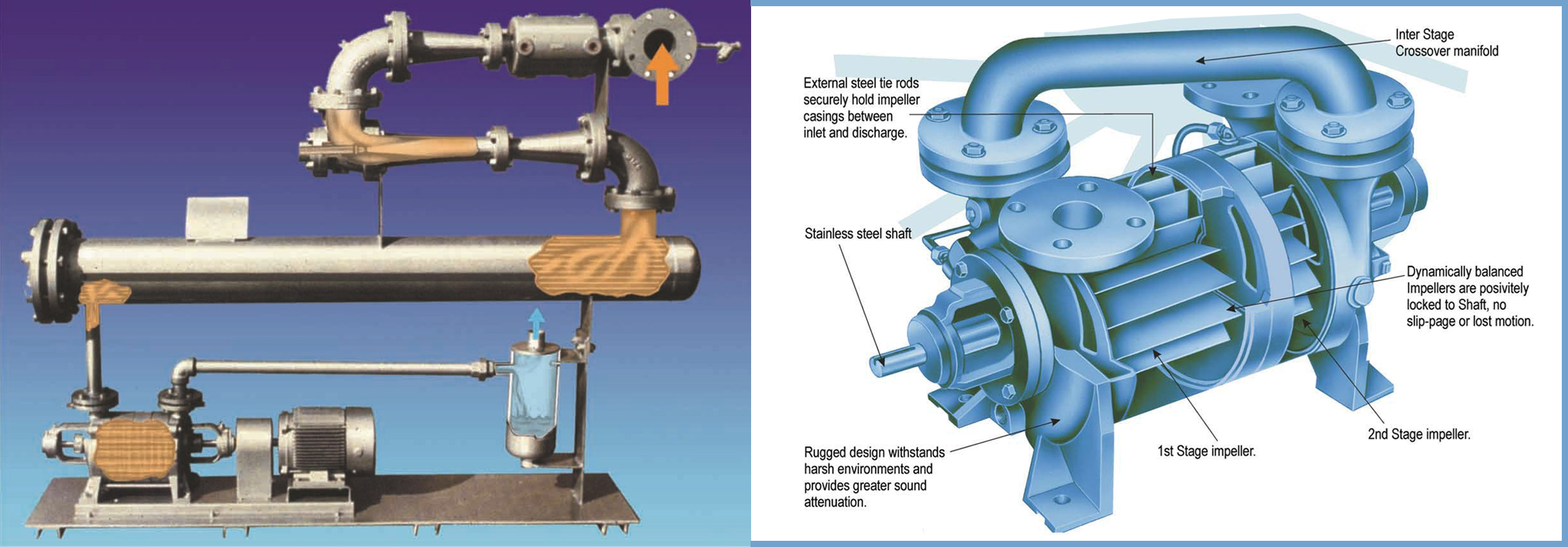

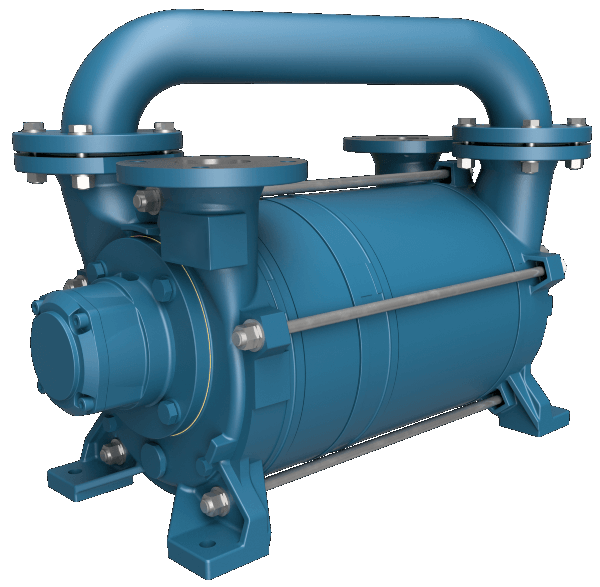

- HIGH CONSTANT PERFORMANCE The durable cast iron and stainless steel components of AGS two-stage vacuum pumps are the result of a rigorous testing and development programme. With almost half a century of AGS's expertise in vacuum technology, these cutting-edge products integrate contemporary engineering principles. Before being shipped out, all Vacuum Pumps undergo a comprehensive assessment of performance.

- Popular sizes of New Generation Liquid Ring Vacuum Pumps, which are produced in India and Germany by AGS, are in stock to ensure prompt delivery.

- BOX FOR EXTRA DEEP STUFFING When combined with minimal friction, packaging made entirely of graphite increases steadiness.

- DESIGN FOR EXCLUSIVE SHAFT SEALING Water is injected directly into the Teflon or nylon ring that is entrapped in the space between graphite gaskets. This water prevents gas leakage and lubrication while penetrating.

- THE GAIN OF EXPERIENCE AGS has been providing high-quality vacuum equipment for your applications since 1973. Choose the ideal Vacuum Pumps for your process requirements with the assistance of the AGS team.

- VERY HIGH RELIABILITY There are no Teflon or rubber balls inside the pumps to deteriorate Vacuum performance. AGS pumps require very little maintenance.

- TECHNICALLY THE MOST ADVANCED OF ITS TYPE ON THE MARKETCompare our designs with the competition. You will not find a competitive offering that can match the overall quality, construction features and performance capabilities of AGS Two Stage Vacuum Pumps

- ANNUAL SAVINGS IN THE TENS OF THOUSANDS OF EUROS PER PUMP DUE TO OPERATIONAL EFFICIENCIES AGS pumps represent the first significant technological advancements in vacuum pumps in nearly half a century.Our substantial enhancements to operational efficiencies result in enduring power cost reductions amounting to tens of thousands of EUROS. In addition to conserving electricity, one can frequently achieve further cost savings by reducing the motor that drives the pump.

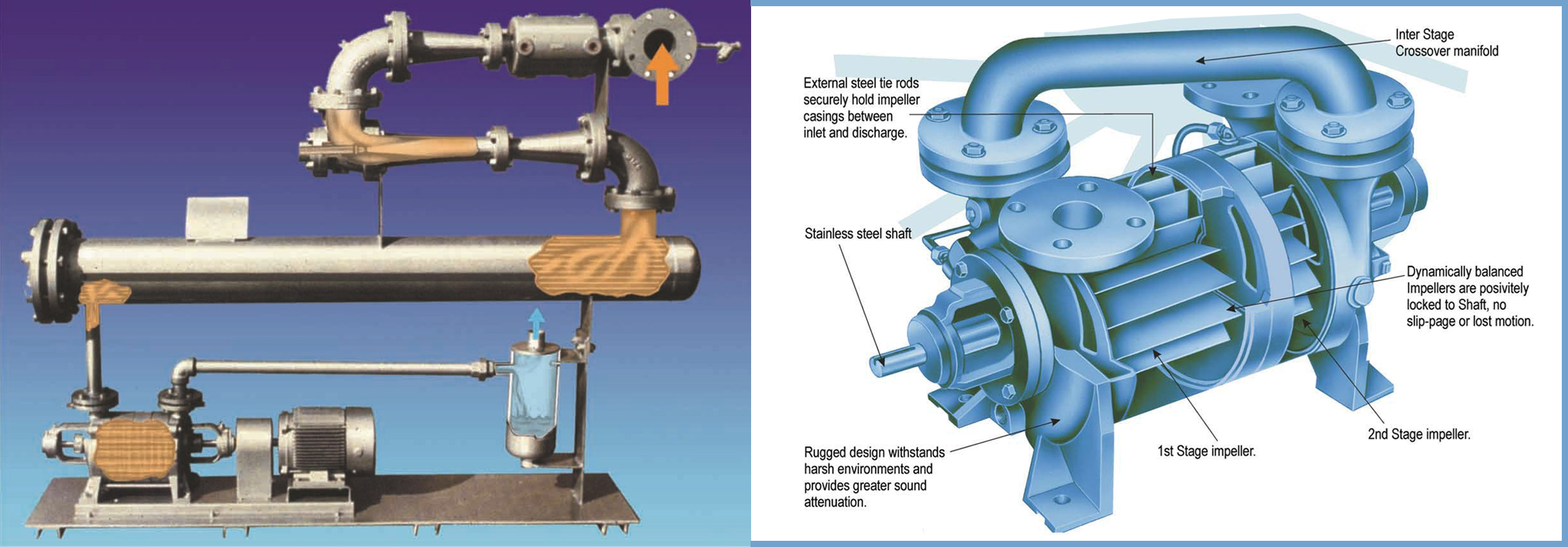

AIR EJECTOR / LIQUID RING VACUUM PUMP SYSTEMS COMBINATION

AGS air operated Ejectors can be installed in the suction line or directly on the suction inlet of a two-stage liquid ring vacuum pump in order to attain suction pressures that are below the capabilities of the pump when operating in isolation. A liquid ring Vacuum pump system that combines an air Ejector and an air ejector can achieve operating pressures as low as 4 torr and shutoff pressures of 3 torr.This further reduction in pressure is accomplished without affecting horsepower or other operational parameters, as the Ejector operates on atmospheric-pressure air as its motive fluid. The quantity of air that passes through the ejector's nozzle effectively safeguards the pump against cavitation, even when operating on closed suction duty. Furthermore, the motive air, which is unrestricted atmospheric air, reduces the pumps' sensitivity to variations in the temperature of the seal water.

AGS air operated Ejectors can be installed in the suction line or directly on the suction inlet of a two-stage liquid ring vacuum pump in order to attain suction pressures that are below the capabilities of the pump when operating in isolation. A liquid ring Vacuum pump system that combines an air Ejector and an air ejector can achieve operating pressures as low as 4 torr and shutoff pressures of 3 torr.This further reduction in pressure is accomplished without affecting horsepower or other operational parameters, as the Ejector operates on atmospheric-pressure air as its motive fluid. The quantity of air that passes through the ejector's nozzle effectively safeguards the pump against cavitation, even when operating on closed suction duty. Furthermore, the motive air, which is unrestricted atmospheric air, reduces the pumps' sensitivity to variations in the temperature of the seal water.

OPERATION

By means of the motive air inlet (A), ambient air at atmospheric pressure is brought in and directed through a converging diverging nozzle (B). The gases or vapours to be processed are entrainment by the high velocity air exiting the nozzle at the suction inlet (C). This entrainment is compressed through the Venturi (D) to achieve the inlet pressure of the liquid ring vacuum pump. The motive air and process gas are subsequently compressed to atmospheric pressure by the pump.

Under certain circumstances, such as when large pumps are used for boosting operations, it is advantageous to incorporate a bypass system into the system to prevent volume loss caused by the ejector throttling effect and to isolate air leakage through the nozzle. This is because, at sub-critical pressure levels, the nozzle air loses its effectiveness as a compressing medium, thereby increasing the workload on the liquid ring pump.

AGS air operated Ejectors can be installed in the suction line or directly on the suction inlet of a two-stage liquid ring vacuum pump in order to attain suction pressures that are below the capabilities of the pump when operating in isolation. A liquid ring Vacuum pump system that combines an air Ejector and an air ejector can achieve operating pressures as low as 4 torr and shutoff pressures of 3 torr.This further reduction in pressure is accomplished without affecting horsepower or other operational parameters, as the Ejector operates on atmospheric-pressure air as its motive fluid. The quantity of air that passes through the ejector's nozzle effectively safeguards the pump against cavitation, even when operating on closed suction duty. Furthermore, the motive air, which is unrestricted atmospheric air, reduces the pumps' sensitivity to variations in the temperature of the seal water.

AGS air operated Ejectors can be installed in the suction line or directly on the suction inlet of a two-stage liquid ring vacuum pump in order to attain suction pressures that are below the capabilities of the pump when operating in isolation. A liquid ring Vacuum pump system that combines an air Ejector and an air ejector can achieve operating pressures as low as 4 torr and shutoff pressures of 3 torr.This further reduction in pressure is accomplished without affecting horsepower or other operational parameters, as the Ejector operates on atmospheric-pressure air as its motive fluid. The quantity of air that passes through the ejector's nozzle effectively safeguards the pump against cavitation, even when operating on closed suction duty. Furthermore, the motive air, which is unrestricted atmospheric air, reduces the pumps' sensitivity to variations in the temperature of the seal water.